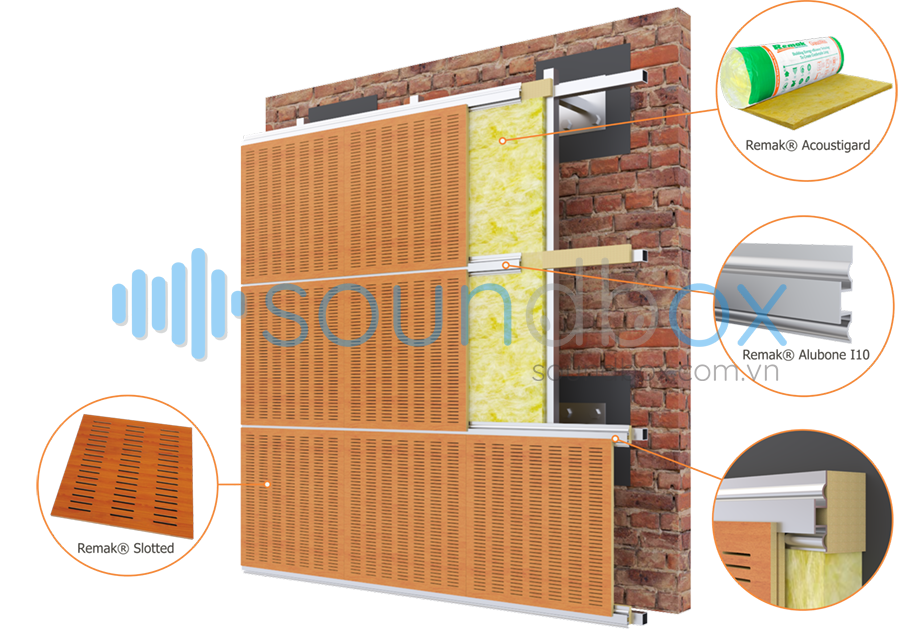

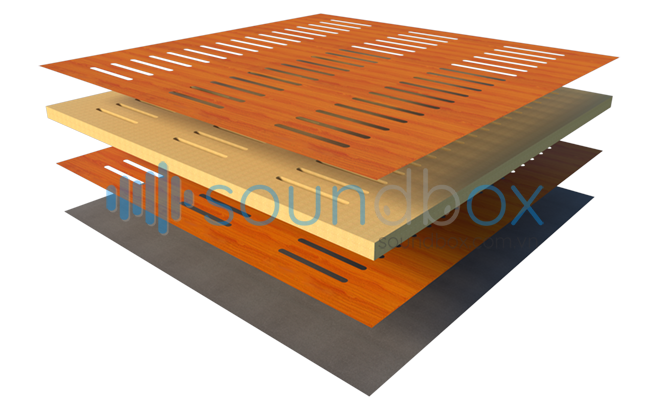

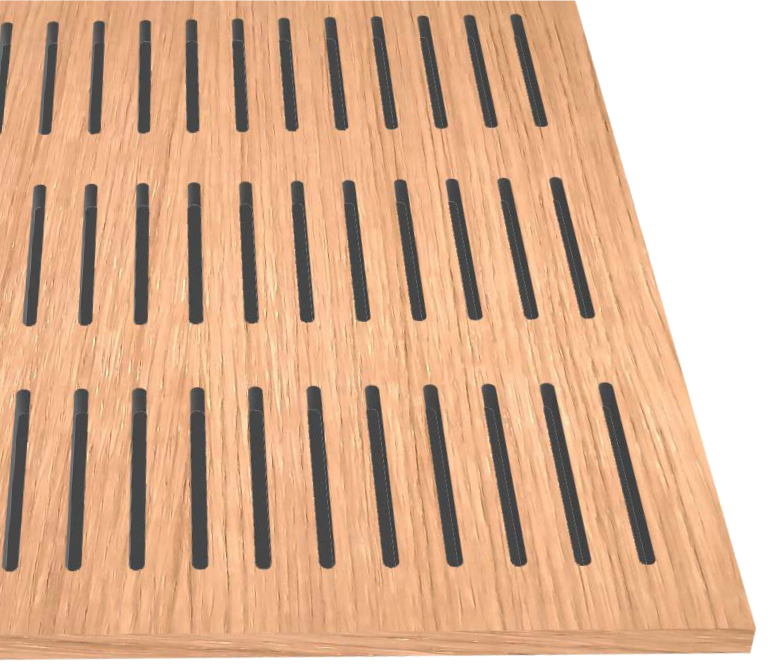

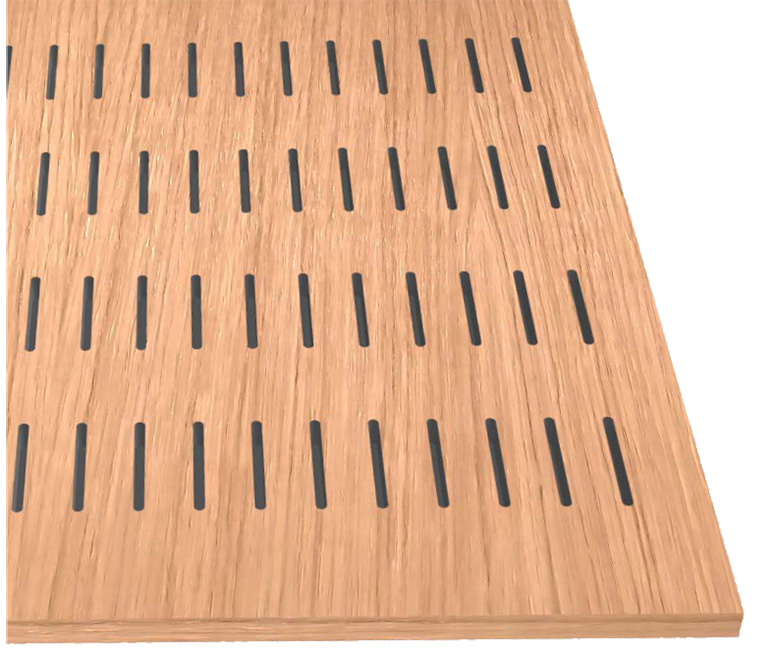

Remak® Wooden Acoustic Slotted is often used effectively for wall acoustics and its aesthetics meet the most demanding requirements of interior designers. These dimensions can be adjusted to your desired designs.

Our products meet E0 standard - European standard that is safe for indoor use, the surface is finished in a variety of colors with many different coating materials, meeting the maximum design requirements, including: melamine, veneer or laminated.

.png)