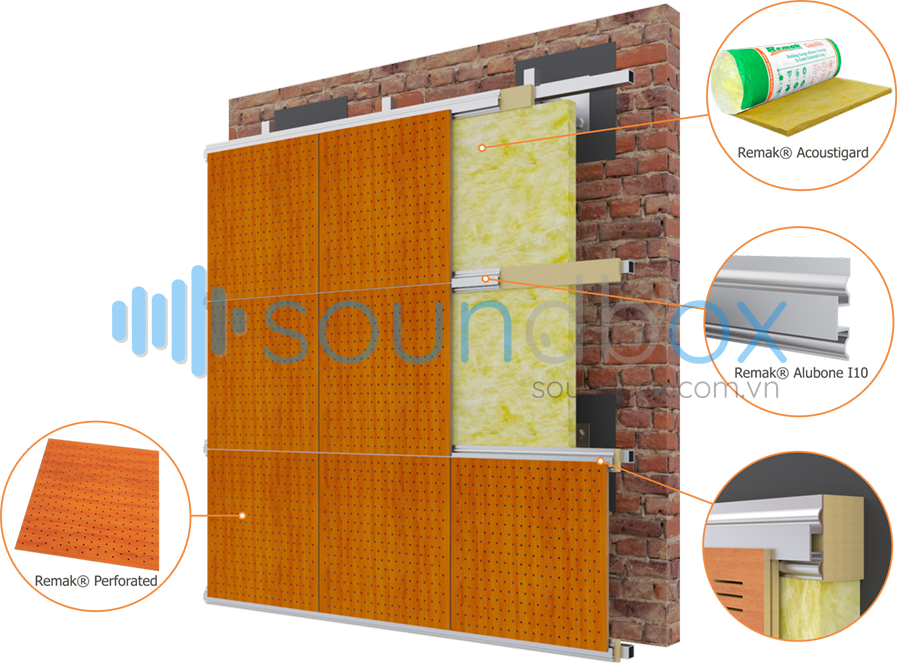

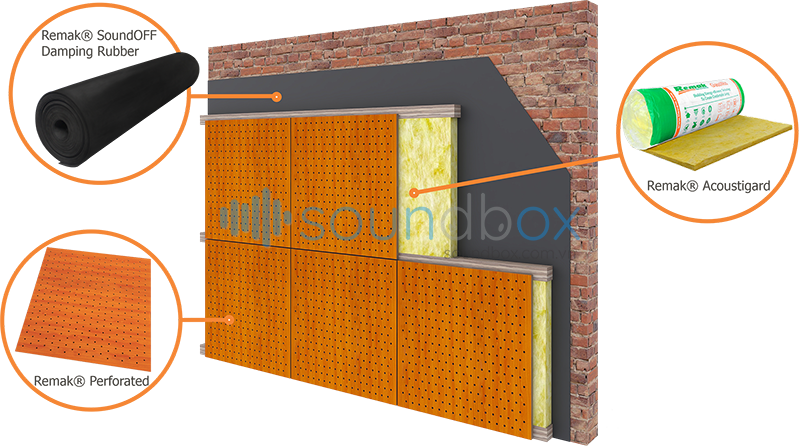

USING ALUMINUM FRAME - ALUBONE

- Clean the wall’s surface

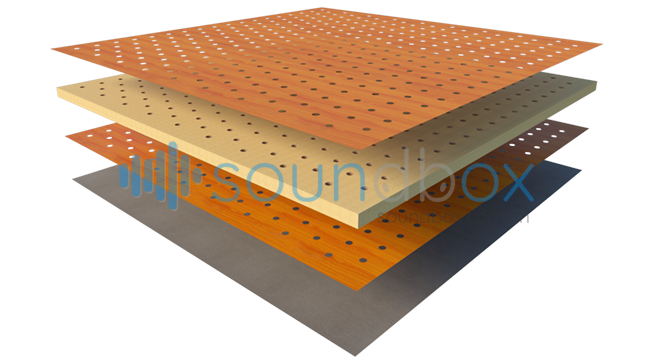

- Stick the Remak® SoundOFF Damping Rubber on the wall

- Locate the positions of the wooden battens by a laser level, the maximum distance between the heart of the wooden bars is 600mm

- Use a concrete nail gun to fix the wooden battens on the wall

- Insert Remak® Acoustigard between the wooden battens

- Screwfix Alubone on the wooden battens.

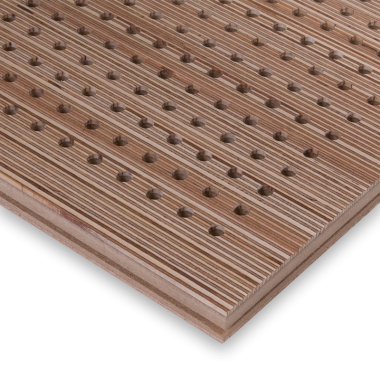

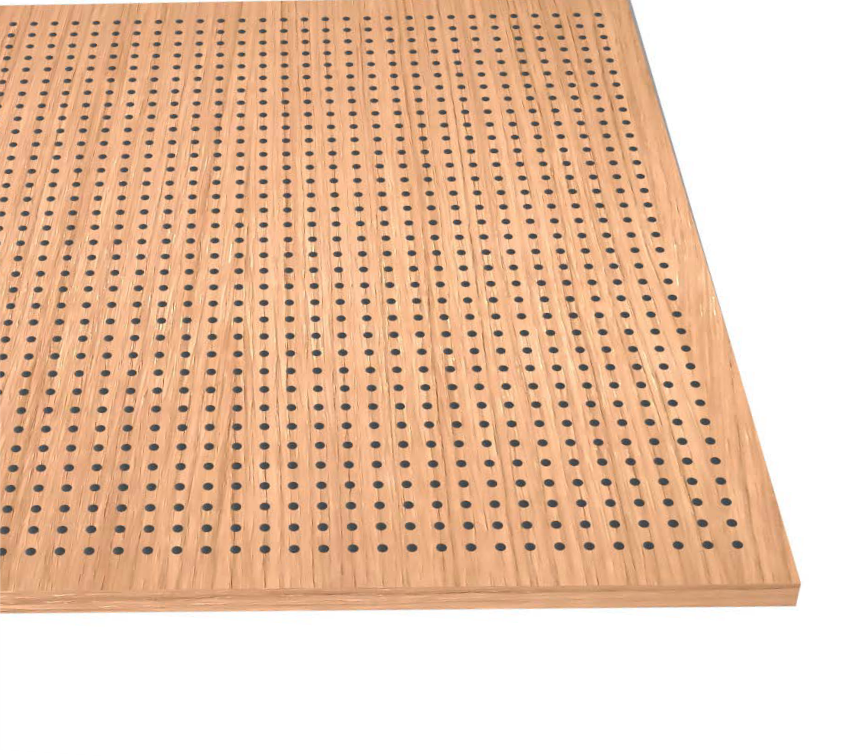

- Insert the Remak® Wooden Acoustic sound with the key into the aluminum bone groove.

Advantages and disadvantages: This construction option is suitable for walls no more than 3m high, simple and fast construction, cost-effective. However, there are a few small nail marks on the surface, reducing the aesthetics.

.png)

.png)

.png)