Remak® Rockwool Acoustigard is a specifically designed product line for sound insulation and sound absorption. The product has the best Price – Performance ratio today compared to similar rock wool products thanks to advanced production technology, optimized for soundproofing and sound absorbing purposes but still retain the fire resistance as well as the stability and sustainability of the product.

- Fire resistance:750°C (ASTM C411-19)

- Heat conductivity coefficient:0.035 (ASTM C518)

- Noise absorption coefficient α:0.75 (ASTM C243-2017)

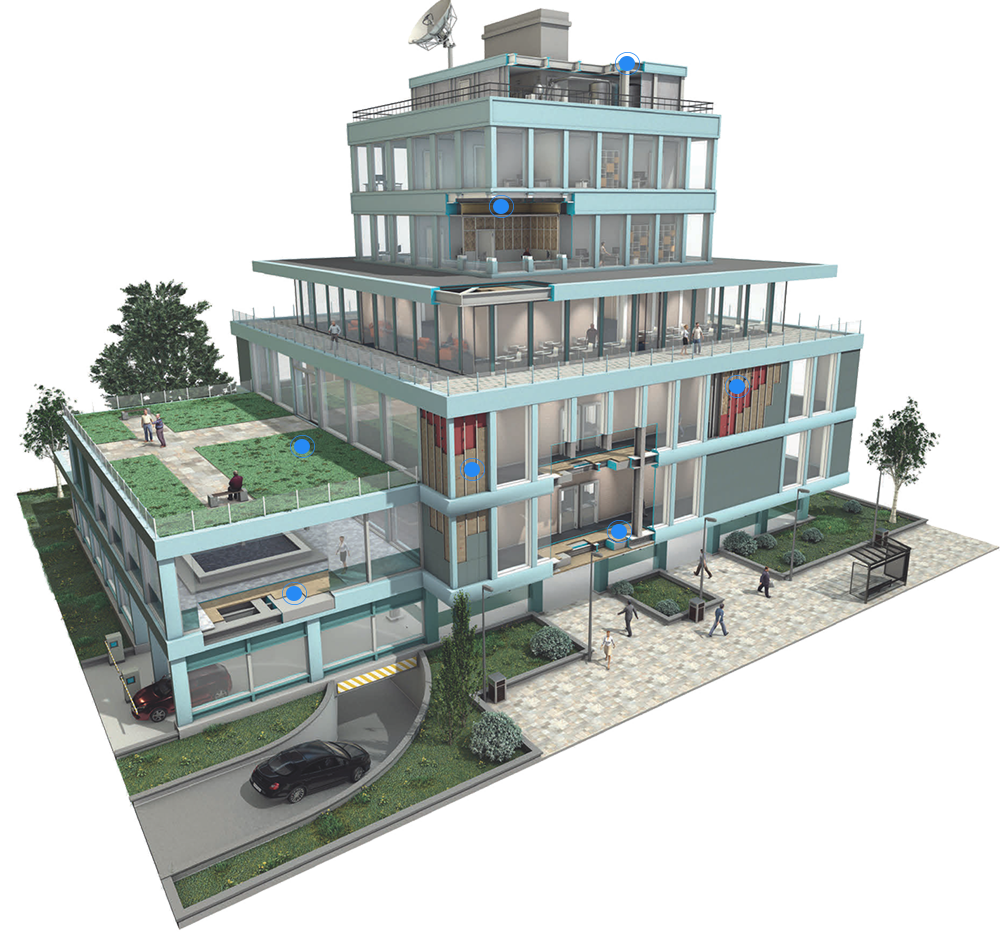

Remak® Rockwool - Comprehensive solution for every project

Unlike most other normal insulation materials made plastic materials, Remak® Rockwool is made 100% basalt. This kind of high-performance natural material itself is mildew resistant, non-flammable, safe and environmentally friendly. Your clients are sure to be pleased to know that their projects are built with the most natural materials.

- Easy installation.

- Efficiency in project life cycle productivity.

- Balance temperature and reduce energy costs.

- Reduce unwanted noise.

- Protect works mold, fire.

![]()

Installation location

Remak® Rockwool can use for floor, office partition, cabin, soundproof box, load-bearing partition, soundproof partition.

Why is Remak® Rockwool Acoustigard the number one soundproofing solution for all construction?

FIRE RESILIENCE

Remak® Rockwool is non-combustible and has a melting point of about 800℃. In an event of a fire, Rockwool insulation can prevent the fire spreading as well as reduce the possibility of toxic smoke and gas formation, providing precious time to save your family and your home.

KHÁNG KHUẨN & NẤM MỐC

Remak® Rockwool được sản xuất từ vật liệu vô cơ và do đó nấm mốc hay vi khuẩn rất khó phát triển trên bề mặt. Điều đó đảm bảo rằng những tác nhân như nấm mốc hay vi khuẩn sẽ không ảnh hưởng đến hiệu suất làm việc của sản phẩm.

LOW THERMAL-EXPANSION COEFFICIENT

Thanks to their low coefficient of thermal expansion, Remak® Rockwool are subject to a very small change in size by temperature. Since the waterproof membrane on the surface (if any) not be damaged

LOW WATER ABSORPTION COEFFICIENT

Remak® Rockwool have a low water vapor absorption capacity of 0.03% (ASTM C 1104) and hold less than 1% water per volume (ASTM 209).

REUSABLE AND RECYCLABLE MATERIALS

Remak® Rockwool are manufactured with a minimum of 40% recycled materials, including: cast iron slag, natural basalt and a portion of waste products that are recovered and recycled in the production process.

ENERGY SAVINGS

Buildings using Remak® Rockwool save a significant amount of energy through a process that prevents heat transferring between the indoor and the outdoor of the building.

HCFC-FREE

Remak® Rockwool meet most of the environmental criteria, does not contain any greenhouse gases or ozone-depleting gases, such as HCFCs, HCs, Asbestos, etc.

ACOUSTIC CAPABILITIES

Thanks to its non-directional fiber structure, Remak® Rockwool have excellent acoustical capabilities, including soundproofing and sound absorption, providing a comfortable, and quiet acoustic environment for the user.

GALERY