Plastic waste

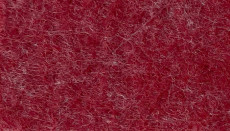

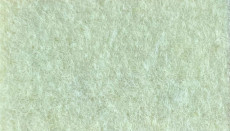

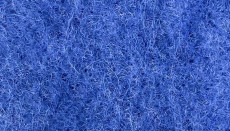

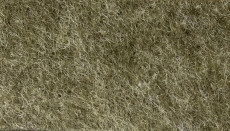

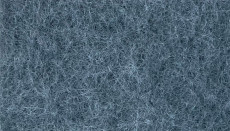

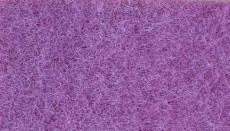

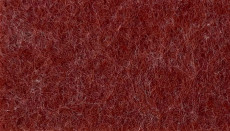

Plastic waste has a long decomposition time, and during the decomposition process up to 100 or even 1000 years, they will be broken down into microscopic pieces of plastic.

These microplastics enter water, soil, air, food... and when people come into contact or eat these microplastics, they will directly affect our health. This is also the cause of many dangerous diseases such as hormone imbalance, respiratory disease, neurological disease, etc.

.png)